The official representative of reliable producers of polymer raw materials in Iran

Thermal stabilizers

Thermal stabilizers or Co-Stabilizers are special mineral compounds and are added to the desired formulation in some special applications of PVC. These compounds are added to the product formulation in very small quantities along with the main thermal stabilizer and increase the performance of the thermal stabilizer several times. An important group of thermal stabilizers are from the hydrotalcite family, and Taraz Polymer Company of Iran is the supplier of these additives for special PVC applications as follows.

Applications of thermal stabilizers

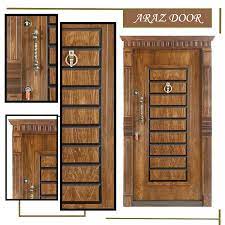

• Synthetic leather • Cable covering • Door and window profiles • Pipes and fittings • Foam board • Geomembrane

Advantages of using thermal stabilizers

• High effectiveness in thermal stabilization • Non-toxic • Free of heavy metals • Suitable for transparent applications • Economical

Impact modifiers

Materials in this category

KM 455 is a product of Indofil company, an acrylic impact modifier suitable for PVC products, with an excellent impact modification capability. This grade can be used in exterior applications such as profiles, pipes, and injection molding and extrusion panels.

Alpha olefin copolymer

Alpha olefin copolymer or Polyolefin Elastomer (POE) are a new generation of polyolefins that are obtained from the copolymerization of ethylene, propylene or butene monomers with comonomers such as 1-butene and 1-octene. POE or alpha olefin copolymer has a low crystallinity and density and is used as a modifier and improver of various polymer properties in automotive, packaging, wire and cable, construction, household and personal appliances industries. Taraz Polymers of Iran is a producer and supplier of various POEs, under the brand name Tafmer, Vistamaxx, Tuflene, for the following applications: • Increasing the impact resistance of PP and PE containers • Modifying the properties of PP and PE compounds used in the production of car parts • Modifying Sewability and mechanical properties of polymer films • Modifying the density and properties of shoe sole compounds • Modifying the properties of wire and cable coating compounds

Metallocene polyethylene – M-LLDPE

The production of PE with the help of metallocene catalysts provides the possibility of adjusting the microstructure and physical-mechanical properties of the resin. Compared to PEs produced with conventional catalysts such as Ziegler-Natta, the mechanical properties of metallocene PEs, such as mechanical strength, are more favorable. Also, the transparency of products produced with these grades is higher. Taraz Polymer Iran is a supplier of metallocene LLDPE (m-LLDPE) under the brand name Evolue from Prime Polymer Company.

Applications of polymer materials

Polymers are used in many industries. Some industries that consume polymers include:

• Packaging Industry

• Household appliance industries

• Automotive Industry

• Health and pharmaceutical industries

• Agriculture industry

• building industry

• Textile Industry

• Electrical and electronic industries

Application of polymer materials in packaging industries:

The biggest consumer of polymers is the packaging industry. These industries mostly use high consumption plastics. The reason for this is the cheap price, ease of processing, recyclability and health of these materials. Packaging is generally divided into two main parts, soft and flexible packaging and hard packaging. Soft and flexible packaging includes a variety of films, including light polyethylene, linear light polyethylene, heavy polyethylene, polypropylene, PVC and PET films. Of course, today other films are also produced by combining with engineering polymers for special purposes.

The use of plastics in the production of various types of nylon bags and replacing them with paper bags is also of high environmental value because it prevents the cutting of trees for paper production.

The production of bags made of polymers such as polyethylene and polypropylene has created a revolution in the packaging industry of various bulk materials such as cement, plaster, beans and grains, flour, bitumen, etc. By replacing paper bags, these bags have led to the development of the packaging industry in this field.

Another general category of uses in the packaging industry is hard packaging, which includes all kinds of bottles. By replacing glass bottles and metal containers, these bottles have made packaging cheaper and raised the level of public health. The use of polyethylene terephthalate bottles has led to the development of the mineral water industry, which, in addition to raising the level of public welfare, has increased health standards. Also, the replacement of glass bottles with PET bottles in the carbonated soft drink packaging industry has also improved the level of hygiene. The use of polyethylene bottles in the packaging of chemicals such as acids and chemical poisons and the replacement of these containers with metal containers has also led to the expansion of the packaging industry.

Packaging of detergents and sanitary and cosmetic materials in plastic containers has also led to the prosperity of the detergent and sanitary industries, which has itself increased the consumption of these materials and, as a result, increased the level of public health. The materials used in this type of packaging mostly include: polyethylene terephthalate, polyethylene, polypropylene, etc. The use of polymer materials in the home appliance industry: one of the largest consumer industries of polymer materials is the home appliance industry. In general, household appliances have become very diverse with modern life, and their expansion has been based on advanced polymer materials as raw materials. Plastic materials have given them many features both in terms of design and in terms of beauty and efficiency. Examples of home appliances that